Simulated Process

Color Separations

Simulated Process Color Separation uses spot colors and halftones

to replicate full-color images with detail and vibrancy

perfect for high-quality prints on dark fabrics.

Always ready to deliver the design you need, right when you need it.

Simulated Process Color

We offer simulated process color separation, using spot colors and halftones to mimic full-color images with high detail—perfect for vibrant, photo-realistic prints on dark garments.

Grayscale color Separation

Grayscale color separation involves converting an image into shades of gray, allowing detailed, single-color screen prints with smooth tonal transitions and depth—ideal for black-and-white artwork.

Image Cleanup & Sharpening

Image cleanup and sharpening enhances clarity by removing imperfections and boosting edge definition, ensuring your designs are crisp, clean, and print-ready.

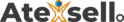

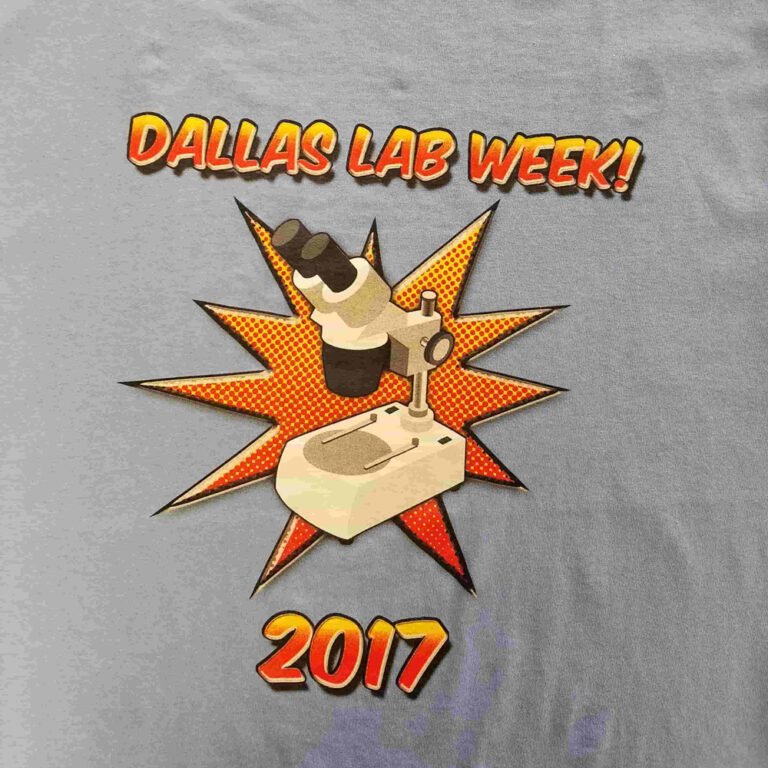

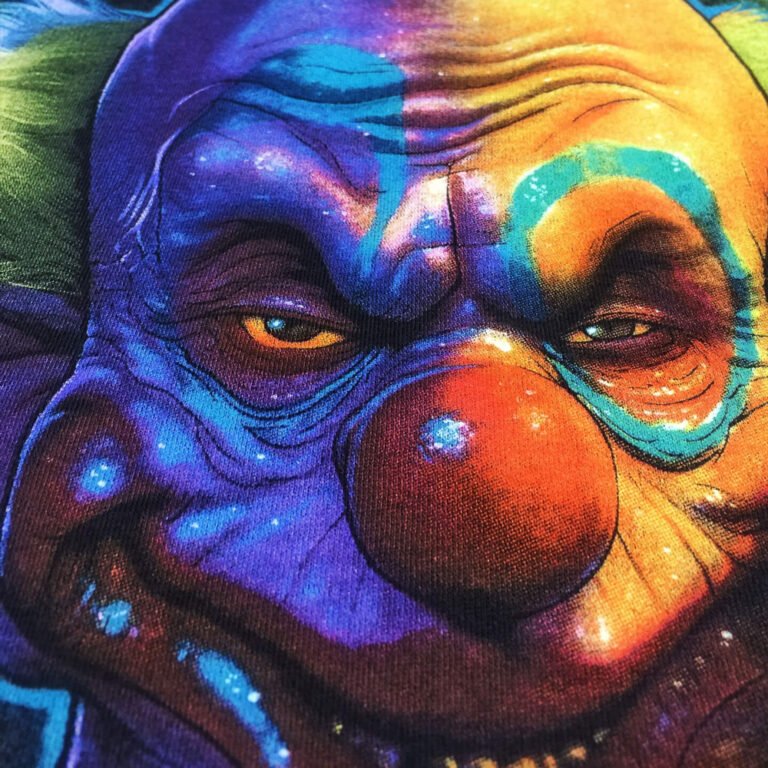

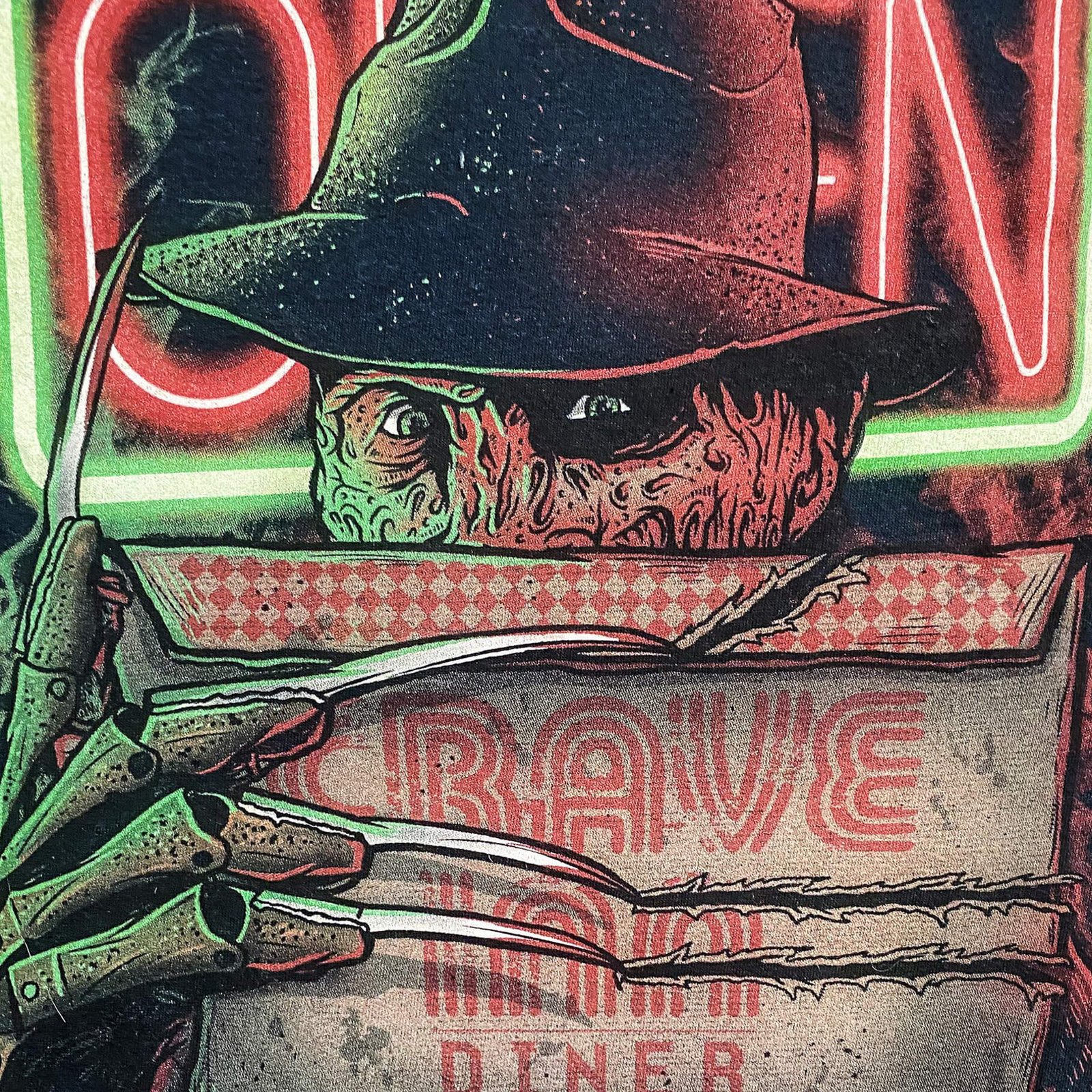

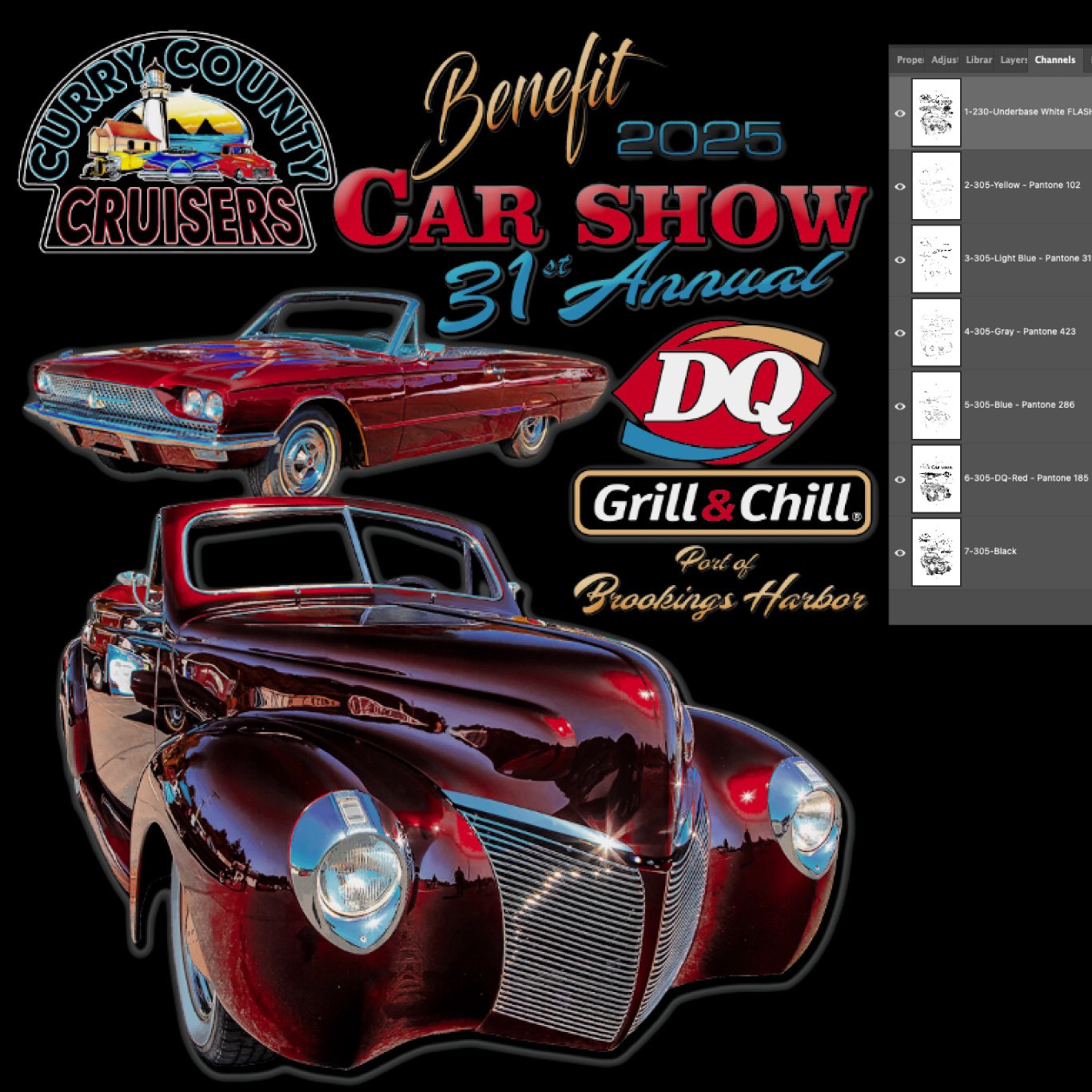

Take a look at some of our Simulated Process Color Separations Work

Simulated Process Color Separations

Simulated Process Color Sep. for day-to-day marketing needs.

$1490/Month

Up to 150 screens

$5/Screen

Within this plan, you get a dedicated designer for:

- Simulated Process Color

- Grayscale color Separation

- Image Cleanup and Sharpening

- Knockout any color background

- Simulated Process Color

- Grayscale color Separation

- Image Cleanup and Sharpening

- Knockout any color background

- Photoshop & Illustrator Color Separation

- Background Removal and Transparency

- Vectorization of Blurry Images

- Redrawing and Remaking Designs

- Photoshop & Illustrator Color Separation

- Background Removal and Transparency

- Vectorization of Blurry Images

- Redrawing and Remaking Designs

Simulated Process Color Separations with Underbase:

Custom Color Separation:

Simulated Process Color is ideal for screen printing detailed images with a vast range of colors. The quality and affordability of the print depend heavily on the artwork and proper color separation. We focus on creating precise color separations using minimal colors to help your business lower production costs.

Use PANTONE® color codes for specific shades in your order. For printing spot color separations, PostScript printers or RIP software offer the best results. If unavailable, separations can still be printed from Photoshop using other methods.

Acceptable File Formats :

- ADOBE PHOTOSHOP (*.PSD, *TIFF, *.EPS - Encapsulated POSTSCRIPT)

- ADOBE Illustrator (*.EPS, *.AI)

- TIFF (*.TIF; *.TIFF - Tagged Image File Format)

- JPEG (*.JPG, *.JPEG - Joint Photographic Experts Group Bitmaps)

Service Include:

- Color separation of your artwork into 10 or less spot colors.

- White Base for dark T-Shirts

- White Base for light colored or pastel T-Shirts

- Highlight White

- Color Correction

- Brightness and Contrast Adjustment

- White Balance Adjustment

FROM DESIGN TO PRINT- WE MAKE IT EASY

How to print sep in AI/PSD?

Creating Halftone Dots without a RIP!

(You can use a Postscript or not-PostScript printer.)

What is Grayscale Color Sep?

Grayscale color separation converts a design into shades of black, white, and gray, allowing you to print detailed monochrome images using just one color of ink—usually black.

What is a halftone?

The halftone is an image that is composed of solid dots of different size and are used to reproduce a continuous tone.

How to set up color profile?

Printing photo-realistic images and colorful t-shirt designs often relies on simulated process separation. This technique utilizes elliptical halftones and layers opaque inks, creating a wide spectrum of colors in the final artwork.

Simulated Process Color Separations:

The Simulated Process technique offers the ability to print full color images on light or dark substrates. Compared to true Process Color, the inks used with Simulated Process are considerable more opaque. This additional opacity provides better coverage on darker fabrics. This fact make them the most widely used method of separation. The Simulated Process uses a basic set of 8 colors for most images. These separations are most often customized for the specific design. The number screens is increased or reduced depending on these image requirements. Even though the inks are more opaque than process, the semi-opaque properties do allow for overprint blending to create a multitude of colors.

Considerations:

Usually requires 8 screens for a full color image.

The partially opaque inks provide better coverage over dark garments.

Why choose us?

At Atexsell , we provide expert screen print color separation services including vector and AI file fixing, DTG/DTF preparation, professional color correction, and all types of separations like index, simulated process, CMYK, and spot color. With experience from over 600 projects, we ensure accurate, print-ready files, on-time delivery, 24/7 support, and no hidden fees. Choose Atexsell for clean, vibrant, and press-ready results — every time.

Fixed Monthly Payment

Fixed Monthly Pricing. No Hidden Surprises.

Unlimited Support

We handle any type of design-related requests—from small to larger projects.

Unlimited revisions

No Limits on Changes. We’ll Keep Iterating Until You’re Satisfied.

Expert Designers

Collaborate with Skilled Designers Who Combine Creativity and Accuracy.

Instant Delivery

Get Your Designs on the Same Day by Upgrading to Our Premium Package.

24/7 Customer Care

Our 24/7 customer care service is always ready to assist you!

Interested in Getting Started?

Got any questions?

What is simulated process color separation?

Simulated process uses spot colors and halftones to recreate full-color images (like photos or complex illustrations) for screen printing, especially on dark fabrics.

Why choose simulated process instead of CMYK or index separation?

Simulated process offers more control over colors and works better on dark garments than CMYK. It also produces smoother gradients and better color vibrancy.

How many colors will my design need for simulated process separation?

It depends on the design, but typically 6–9 spot colors are used, including highlights and shadows. I aim to minimize colors without sacrificing quality.

Can you show me some samples of your previous work?

Yes, you can visit my portfolio.

Do you create an underbase in the file?

Absolutely. A white underbase is essential for printing on dark garments and is always included when needed.

What type of files do you deliver?

I provide layered, print-ready files in formats like PSD, AI, or PDF, with clearly labeled channels for each ink color. Halftones are rasterized for direct output if required.

Can you match specific Pantone colors in the separation?

Yes, if you have specific PMS colors you’d like matched, I can incorporate and label them accordingly for your printer.

What resolution do you need for best results?

300 DPI at actual print size is ideal. Low-resolution files may reduce quality, but I can enhance or recreate parts if needed.

How long does the simulated process separation take?

Turnaround is typically 2–4 business days, depending on the complexity of the artwork and number of colors.

What are your designer's working hours?

Designers work on Monday to Friday, from 09:00 to 18:00 (GMT+2).

What is your 7-day money-back guarantee?

All our plans come with a full 7-day money-back guarantee. If, after several design requests, you still don’t think Atexsell is the right fit for you, we will refund 100% of your initial membership fee.

Can I pause my subscription?

Yes, you can pause your subscription for up to 7 days, but only during the 3rd month of your subscription.